Hi fellow GB fans. Its been a while since my last post so its time for a fairly large update.

Last weekend I reached a bit of milestone for my build. I have now finished making and mounting all of the steel work on the main pack (bar the gun hook which I will make later as I currently don't have the right thickness aluminium plate.)

So lets get started with catchup photos.

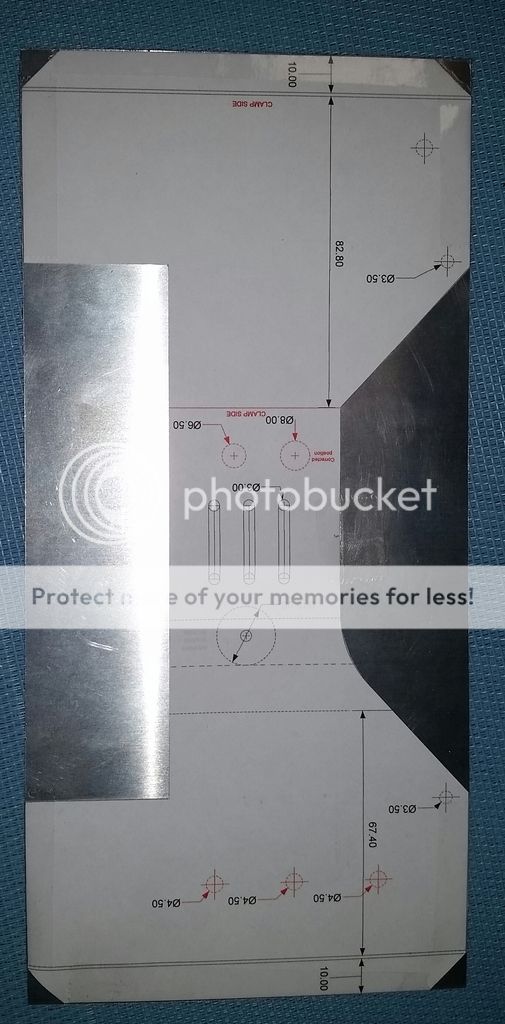

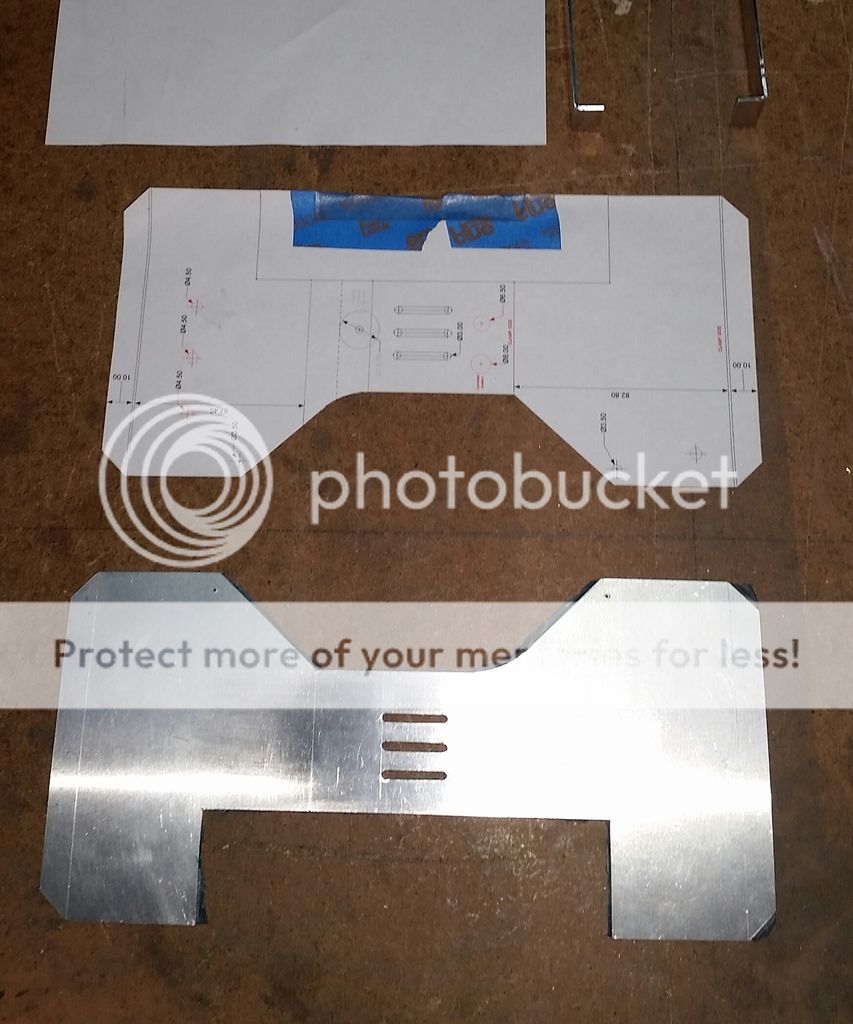

I marked out and cut the motherboard out of 3mm thick aluminium sheet. I also made mounting brackets out of 1/8" thick, 1" x 2" angle which I JB welded an extra plate to(not shown in the photos unfortunately) for extra screw thread to hold the shell on. I pop riveted these to the MB using those wide head rivets.

The next task was to put the shell on a diet and remove some of the internal walls that were adding weight for no gain. Plus removing these walls has created pathways for the future cable runs inside the pack. I'm in two minds about showing inside photos, my early welding wasn't the best as I was starting out, plus you guys may just not be interested..hmm if there is enough interest I'll post a couple in the future.

Time to mount my Alice frame (Obtained from the GBFans store) to the pack using the hockey puck method. Ultimately I would like to change the Alice frame to a genuine 1980's one to be a bit more authentic with the build.

Now I must say that it quite difficult to find affordable hockey pucks locally in Brisbane, so I had to resort to EBay. I ended up buying three thinking that I would have a couple of spare if I stuff the half moon cut up, ultimately I ended up using all three in a PssdffJay style mounting arrangement. Now I must fess up that I'm a 41 year old that has never before held a hockey puck, so it was amusing to play with them for a while before getting down to business.

So the next photos shows tings that probably would get you arrested in Canada.

To cut the pucks I made a sacrificial holding board that I could securely mount on my miter saw, and keep my fingers safe.

I was surprised how easily the saw cut the rubber. But I took it nice and slow just to be careful of the saw blade jamming up.

Now for the bottom mounts. Make the first cut then spin the puck around for the second, using gaffer tape and wood blocks to hold things down safely.

Alice frame sat in place.

Now unfortunately I got so tied up with the build I forgot to take photos, well except for a boring photo of the ribbon clamp build. (Not sure why I took this one and forgot to take more.)

Anyway, after much part positioning, measuring, changing my mind, repositioning, studying photos of the real packs, etc, etc I have arrived at this.

Not all of the small fittings are on in the above photos, and some holes are yet to be drilled out and tapped for these.

I'm fairly happy with how it turned out, not perfect but much better than I thought it would be when I started. I have a minor amount of putty filling to do under the forward edge of the HGA and Booster tube base (near the PPD) where the aluminum pulled in a bit from the welds (or was eroded away from excessive sanding

, but nothing more than a mm in a couple of places. My biggest error so far is one from the start when I welded up the EDA, I spent to long welding the EDA to the gearbox and caused an internal wall to sag, which ultimately had the effect that the bottom of the EDA slopes inwardly from the top to the motherboard. Hopefully with the ribbon cable on and other parts and painted black it wont be too noticeable. Plus I did the calcs, and worked out that the pack will be safe to use so long as I don't cross the streams!

So that's it, time to start on the thrower build. All comments, criticism welcome as always.

Cheers,

Pete.

GB1 and GB 2 Uniform Build Thread:

GB1 and GB 2 Uniform Build Thread:

- By Threadender

- By Threadender - By The_Y33TER

- By The_Y33TER