Well, today's update definately lives up to the "idiot" name of this thread. *sigh*

Yesterday my bolts turned up, so I decided to sort through them while watching a certain film we all know and love. It was far too hot to do any real work.

Anyway, back to today's fiasco-fest. First thing I did was go back to the ion arm holes I pre drilled last time. Of course, I'd drilled them one size too big, hadn't I? The bolts fitted in perfectly before a tap had even seen the hole.

Bugger.

Let this be a lession, kids: Never drill a hole before you have the bolt in front of you!

Right, out with the Milliput, fill the smeggers in!

OK, so that will have to set before I can try again. While I had the putty out, I touched up that nasty chip beside the n filter hole.

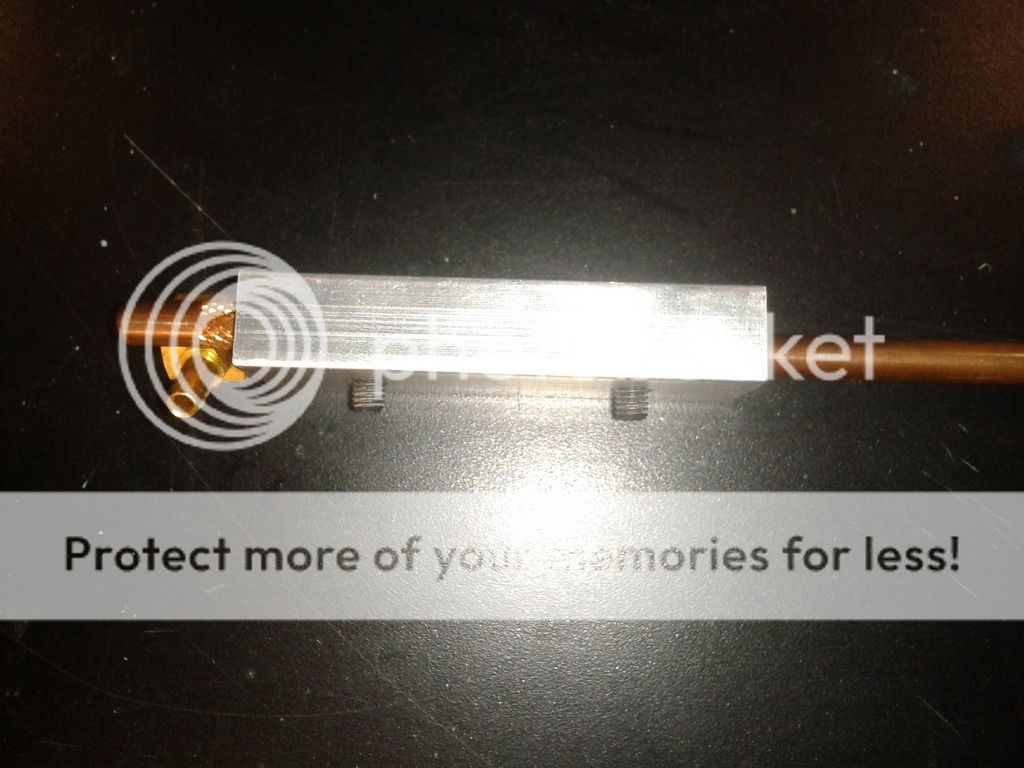

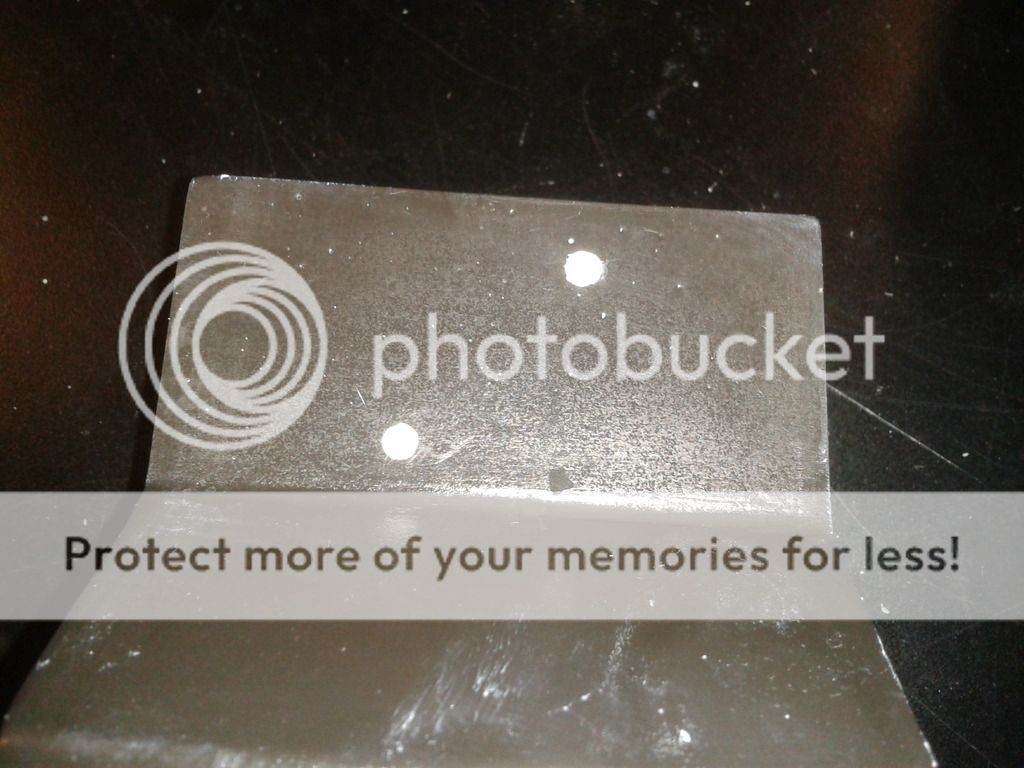

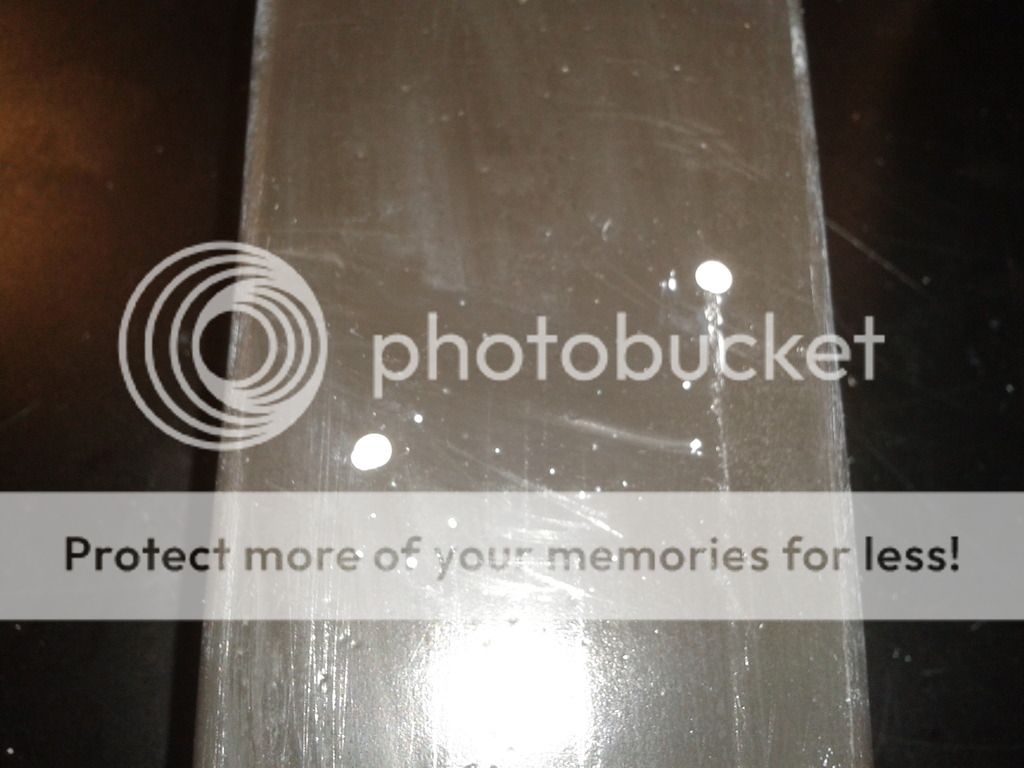

Let's do some nice easy decorative bolts that don't have to hold anything. That's can't go wrong, can it? Four holes drilled in the HGA...

Let's tap some threads!

... So there I was, tapping away, when suddenly with a worrying CRUNCH sound, the tap went straight through the resin. The part is not damaged, thank smeg, but it stripped all the thread and widened the hole to the point the bolt slides through without gripping. This happened on two of the four holes.

I'm starting to come to the conclusion that tapping threads in resin is not going to work. Might have to try a diferent method. But hey, I'm learning!

... Learning exactly why I've always stuck to plastic aircraft kits or Lego. I suck at this.

But this is what is

would look like if I hadn't ballsed it up:

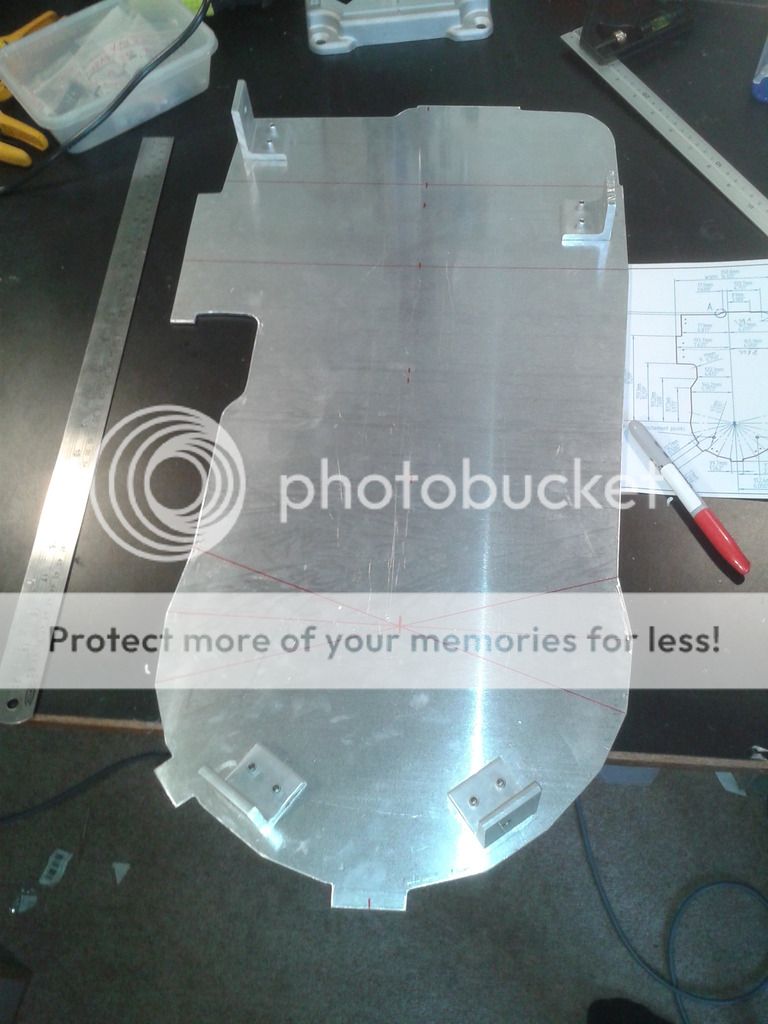

With the shell being left alone while the Milliput sets, and reluctant to ruin any more of the resin parts until I can rethink my stratagy, I turned my attention to the motherboard.

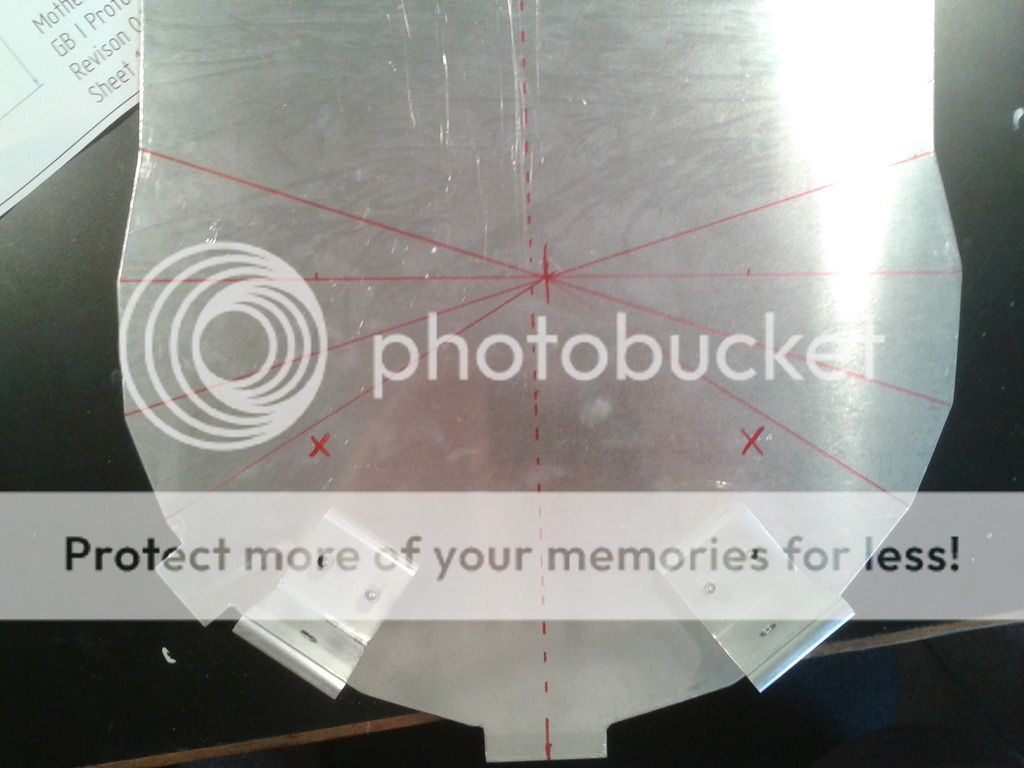

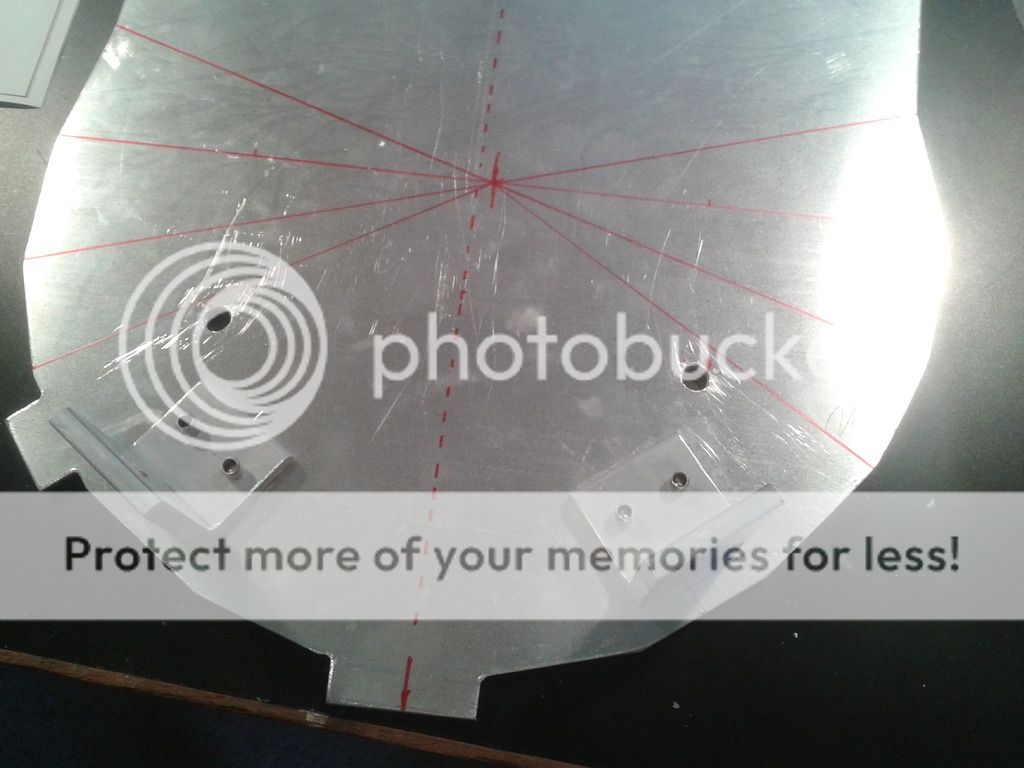

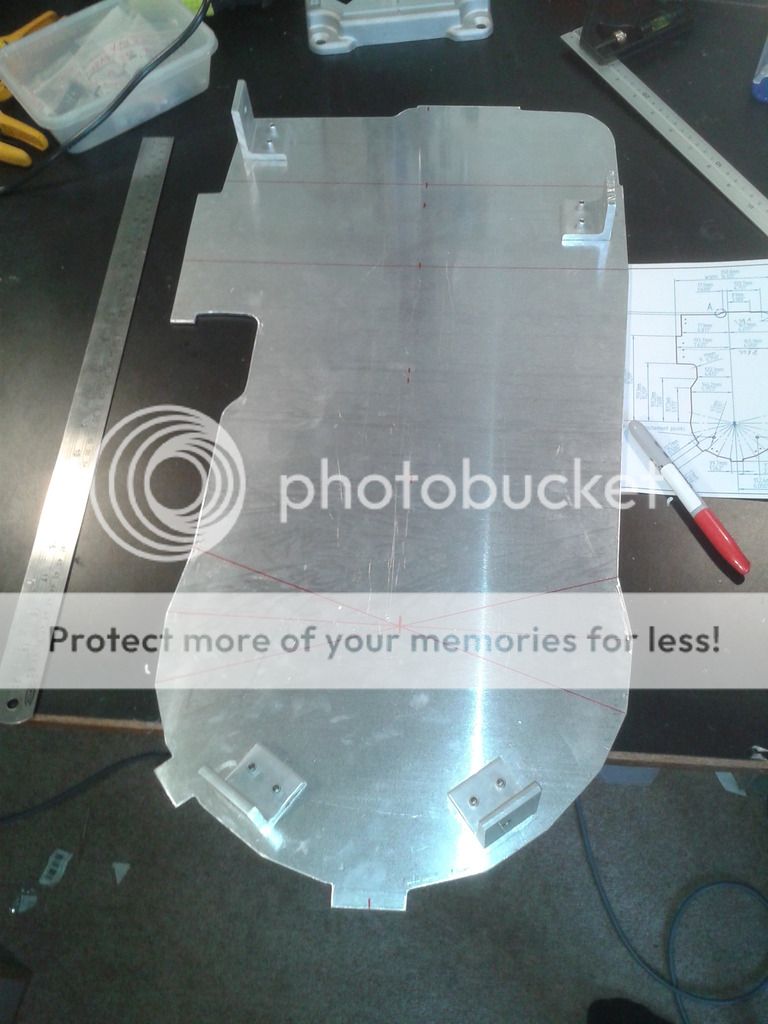

Sooner or later, I'll need to start making holes in it. But first, I'll have to find the centre line. Armed with Stephan's plans, a steel rule, and a sharpie, I started marking things out.

Now naturally, there will be a few differences between the plans and Nick's mobo. Some of the measurements line up, some of them don't... None of them look even remotely straight to the eye. I have no doubt that this is a cock up on my part somewhere, so before I go drilling, I thought it best to show what seems to be the best compromise. Does this look even close to right?

The longer lines are the measured "middle" points. Dotted line seems to be the best fit. (Apologies for the flash flare).

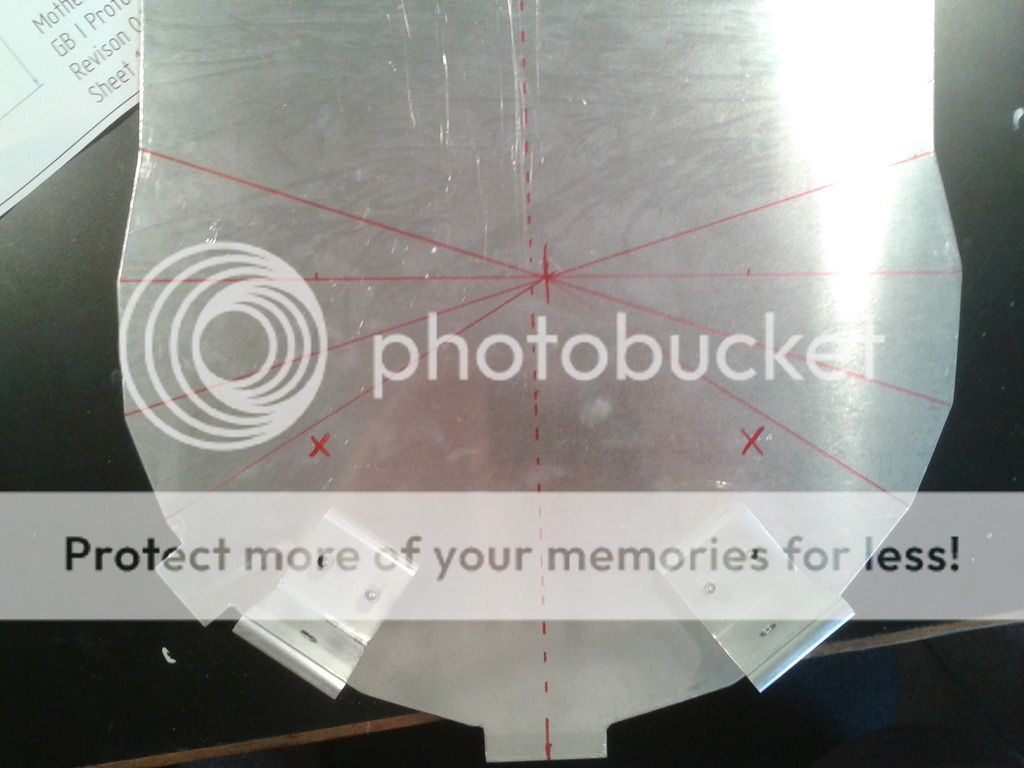

Based on those measurements, I figure the bolts for the A.L.I.C.E. frame go here (X marks the spot).

What do you experts think? What are the key points to use when finding the centre? What am I doing wrong?

What is the answer to the great question of life, the universe, and everything?What exactly was the point of typing those numbers in to the computer in LOST? ... Why am I sitting here worring about this at almost 8pm on a Saturday night?

AAAAARRRRGGGHHH! You know, this project could drive a guy to drink... Hey,

there's an Idea...