- August 26th, 2015, 9:25 pm#4842291

First I want to say that this is going to be a slow process, but wanted to document the process since I have appreciated the build threads that others have posted.

There are photos available from packs that are supposed to be used in the upcoming movie and since the movie is not out yet, I am sure to violate future defined accuracy, but am just in the mood to make something in my spare time and I also want to use my 3D printer.

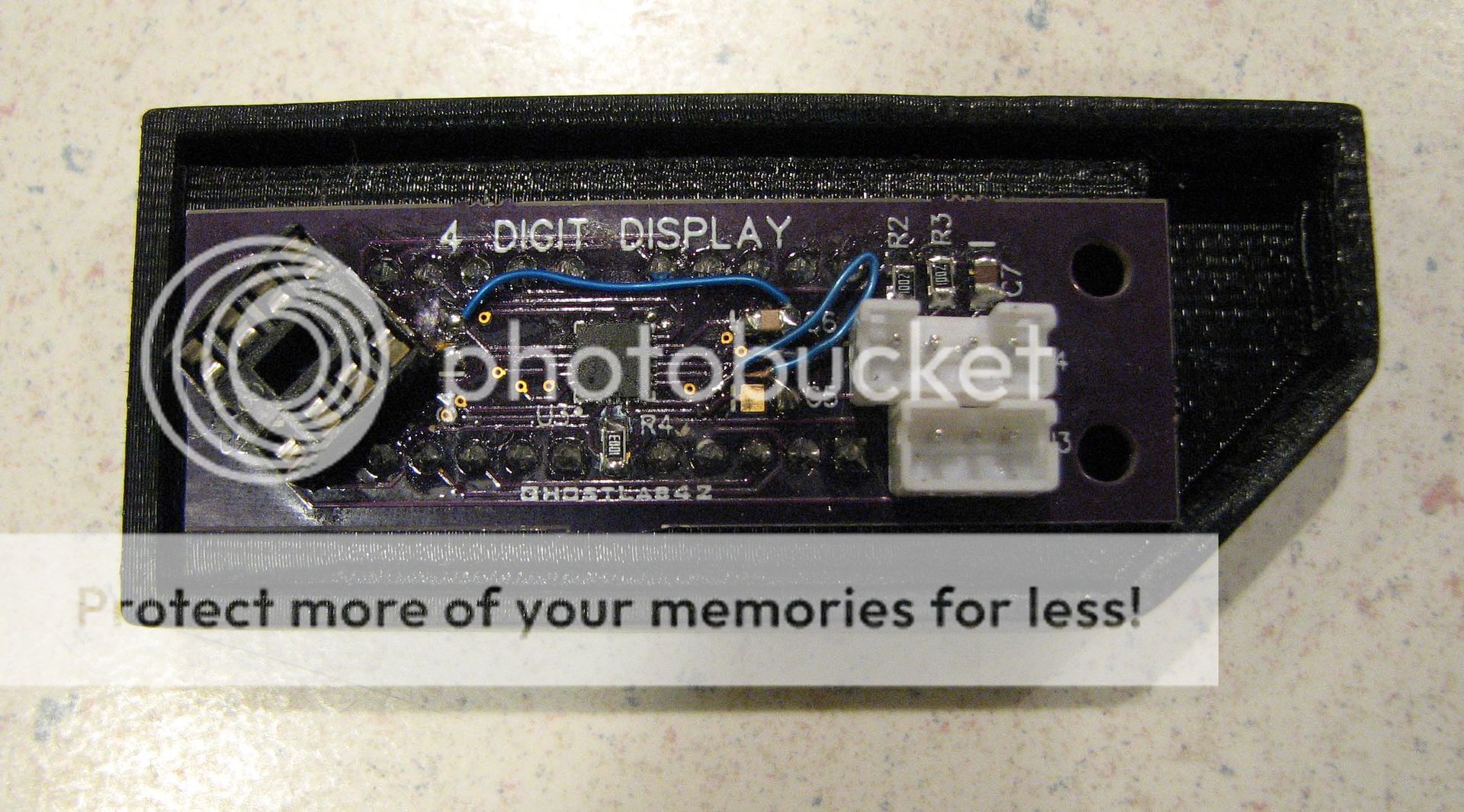

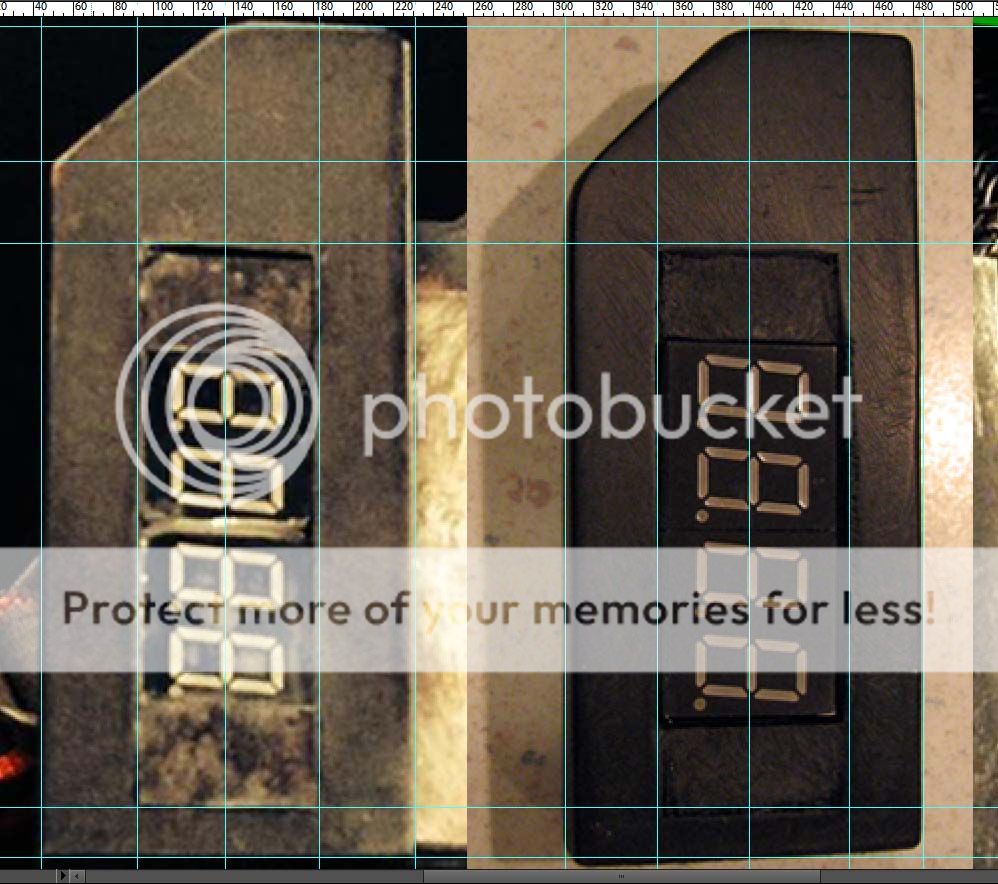

Also note I love blinky lights and sound, so this is going to include those!

For the main dome, I want something interesting to look at even if you cannot see it very well in the photos so I designed this:

The dome and rings need to be nearly 12" in diameter, and I have Flashforge Dreamer 3D printer and it has a build volume of 9.1" x 5.9" x 5.1", so it won't fit in one piece...

I am choosing ABS since it is the strongest and is not water soluble. I use a lot of black, so why not start with that. Currently I am using Hatchbox 1.75mm ABS filament and it is working fairly well. I tried Octave and the layer-to-layer adhesion I just couldn't get dialed in.

Lots of 3D printing trials and errors, that I won't go into here, but lets just say it is not plug and play and I spend a lot of time just trying to make the printer output something usable.

So I cut the model into 5ths due to the symmetry of the design and that will just barely fit on the printer.

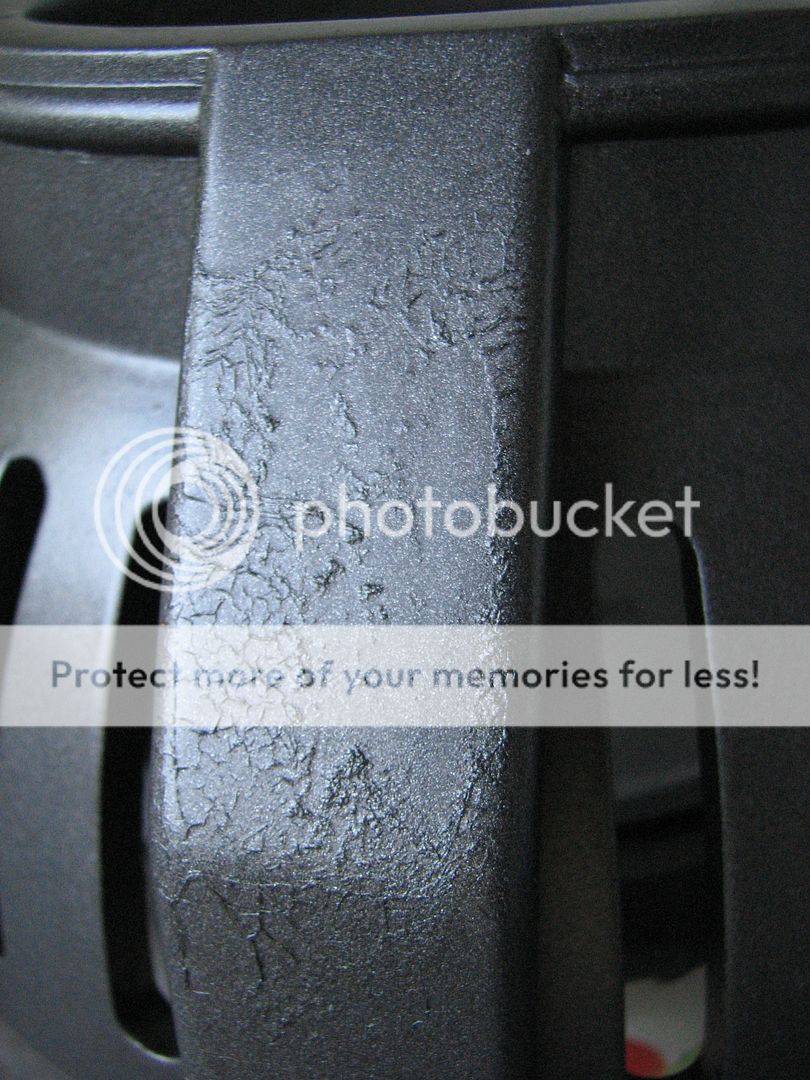

Here is one part:

And another angle showing the inside:

It takes 11 hours to print this, so it would take 55 hours if I could print the hole inner dome on a bit printer? This is a part I have redesigned multiple times - each time I print it I think of some change I want and I finally just had to say close enough and time to print up lets get this thing printed!

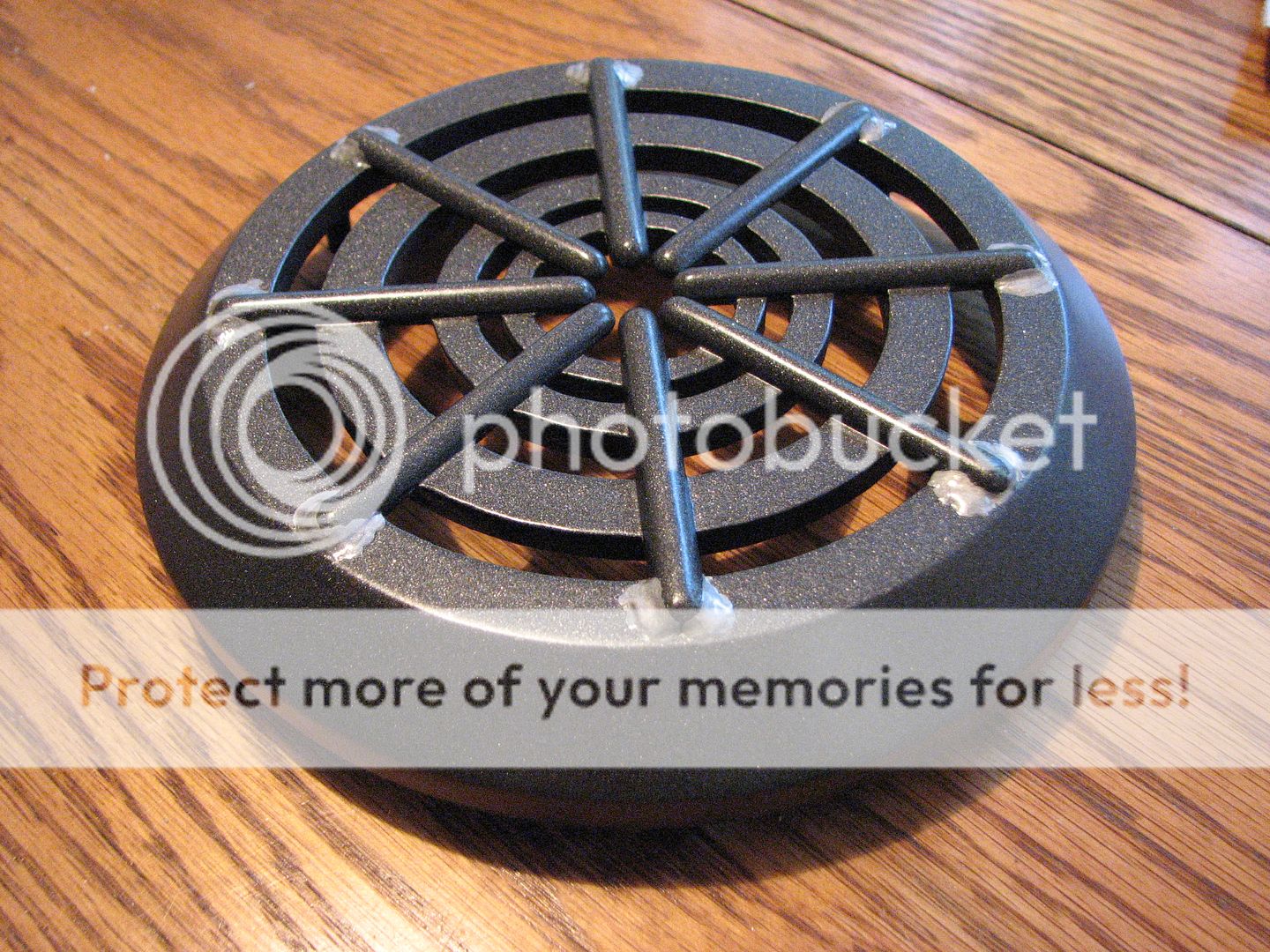

I added holes through the part that are just slightly larger than the filament so I could thread the filament through and use it align and hold the parts together.

After days (and days) of printing, here is the test fit of the 5 parts with filament threaded through them with enough space between the parts that you can see the 4 lengths of filiment threaded through the pieces:

Here is the test fit with the pieces pressed together closely and also a trial fit of the LED ring.

I really want to have it in one piece so gluing will be the next step. One fun note: the LED ring has a larger diameter than any opening in the dome so this will be something to resolve later - just minimize the pain, not a show stopper and I am not willing to wait to figure that out...

There are photos available from packs that are supposed to be used in the upcoming movie and since the movie is not out yet, I am sure to violate future defined accuracy, but am just in the mood to make something in my spare time and I also want to use my 3D printer.

Also note I love blinky lights and sound, so this is going to include those!

For the main dome, I want something interesting to look at even if you cannot see it very well in the photos so I designed this:

The dome and rings need to be nearly 12" in diameter, and I have Flashforge Dreamer 3D printer and it has a build volume of 9.1" x 5.9" x 5.1", so it won't fit in one piece...

I am choosing ABS since it is the strongest and is not water soluble. I use a lot of black, so why not start with that. Currently I am using Hatchbox 1.75mm ABS filament and it is working fairly well. I tried Octave and the layer-to-layer adhesion I just couldn't get dialed in.

Lots of 3D printing trials and errors, that I won't go into here, but lets just say it is not plug and play and I spend a lot of time just trying to make the printer output something usable.

So I cut the model into 5ths due to the symmetry of the design and that will just barely fit on the printer.

Here is one part:

And another angle showing the inside:

It takes 11 hours to print this, so it would take 55 hours if I could print the hole inner dome on a bit printer? This is a part I have redesigned multiple times - each time I print it I think of some change I want and I finally just had to say close enough and time to print up lets get this thing printed!

I added holes through the part that are just slightly larger than the filament so I could thread the filament through and use it align and hold the parts together.

After days (and days) of printing, here is the test fit of the 5 parts with filament threaded through them with enough space between the parts that you can see the 4 lengths of filiment threaded through the pieces:

Here is the test fit with the pieces pressed together closely and also a trial fit of the LED ring.

I really want to have it in one piece so gluing will be the next step. One fun note: the LED ring has a larger diameter than any opening in the dome so this will be something to resolve later - just minimize the pain, not a show stopper and I am not willing to wait to figure that out...

GB1 and GB 2 Uniform Build Thread:

GB1 and GB 2 Uniform Build Thread:

- By hawkbatsquadron

- By hawkbatsquadron