- August 16th, 2016, 4:54 pm#4877306

Hello all!

Well I'm new here, but not new to the hobby....but I wanted to dive right in. I woke up one day last week with the desire to build the reboot pack, so here I am.

So far I have the plans for the motherboard off to the machine shop, and hopefully they will be done in the next week or two and I've started doing some of the 3d printed parts. Most of the 3d printed parts will eventually be molded and made out of fiberglass. My buddy and I are working on packs together, so there is no sense in cleaning up parts twice, not to mention they'll hold up longer if they are fiberglass.

The bowl inside of the syncrotron will be the only part that stays as a 3d printed piece. Since it will never really be seen, and it's an exceptionally complex piece, it just isn't worth molding.

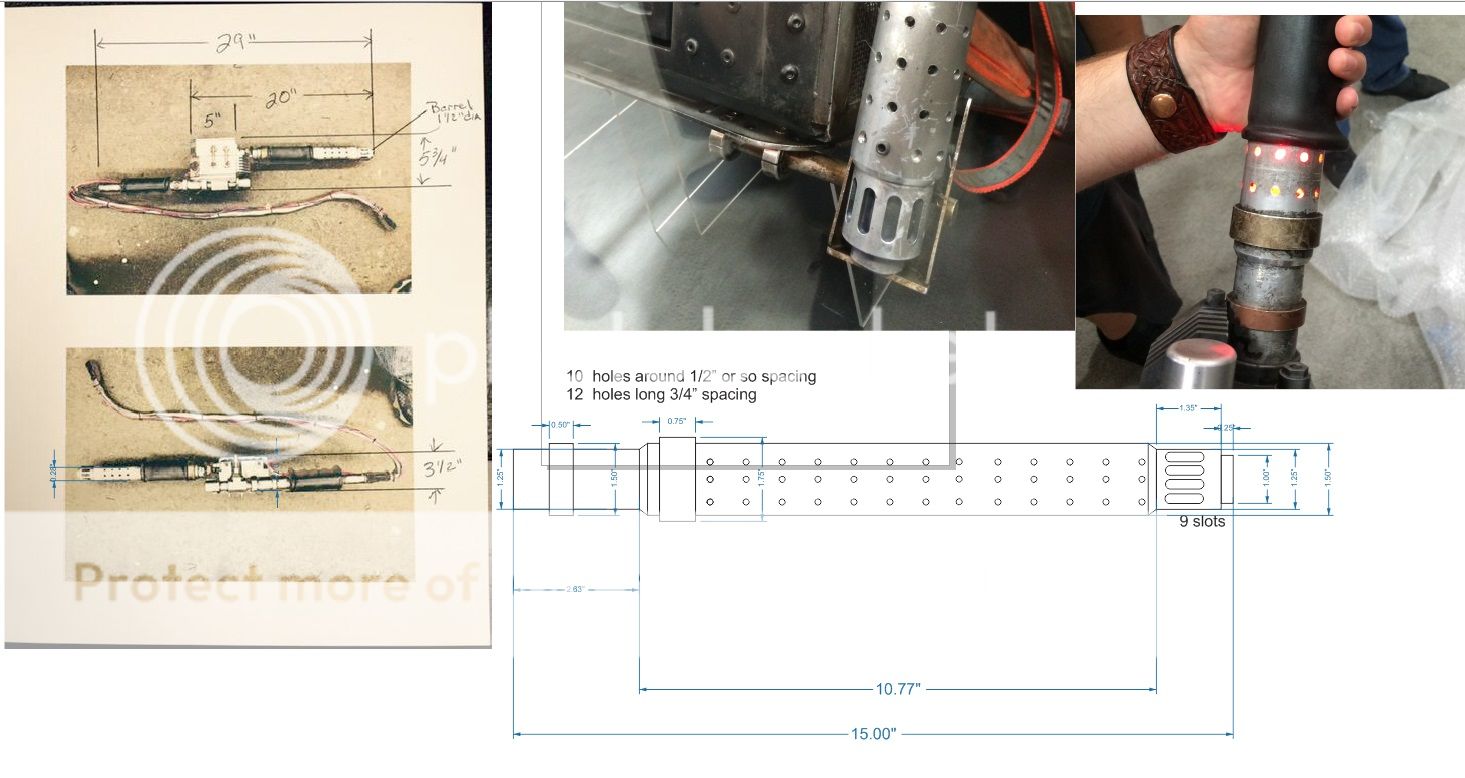

I'm using TheLegendOfMart's beautiful thrower box that he's shared on Thingiverse. I'm probably going to make a few small upgrades to it to enhance the 3d printed details. I'm replacing the back plate with a laser cut piece I made, and I'm probably going to replace any screws with real ones in the final version. This will be fiberglass when it's done too.

I've got some parts on order while I wait on the motherboard to come in, and then I'll get into this a little more deeply.

Thanks for letting me play guys and girls!

Gregg

Well I'm new here, but not new to the hobby....but I wanted to dive right in. I woke up one day last week with the desire to build the reboot pack, so here I am.

So far I have the plans for the motherboard off to the machine shop, and hopefully they will be done in the next week or two and I've started doing some of the 3d printed parts. Most of the 3d printed parts will eventually be molded and made out of fiberglass. My buddy and I are working on packs together, so there is no sense in cleaning up parts twice, not to mention they'll hold up longer if they are fiberglass.

The bowl inside of the syncrotron will be the only part that stays as a 3d printed piece. Since it will never really be seen, and it's an exceptionally complex piece, it just isn't worth molding.

I'm using TheLegendOfMart's beautiful thrower box that he's shared on Thingiverse. I'm probably going to make a few small upgrades to it to enhance the 3d printed details. I'm replacing the back plate with a laser cut piece I made, and I'm probably going to replace any screws with real ones in the final version. This will be fiberglass when it's done too.

I've got some parts on order while I wait on the motherboard to come in, and then I'll get into this a little more deeply.

Thanks for letting me play guys and girls!

Gregg

- By pda4ever

- By pda4ever - By UncannyGirl

- By UncannyGirl