- March 20th, 2015, 9:07 pm#4829668

So, Alex, Phil, and I decided to collaborate and build a set of GB1 traps for ourselves. I've converted Stefan's plans to AutoCAD and changed the dimensions to fractional. I'll be cutting the bodies from 1/4" and 1/8" ABS. I'll also make the CAD files publicily available once I finish a few tweaks.

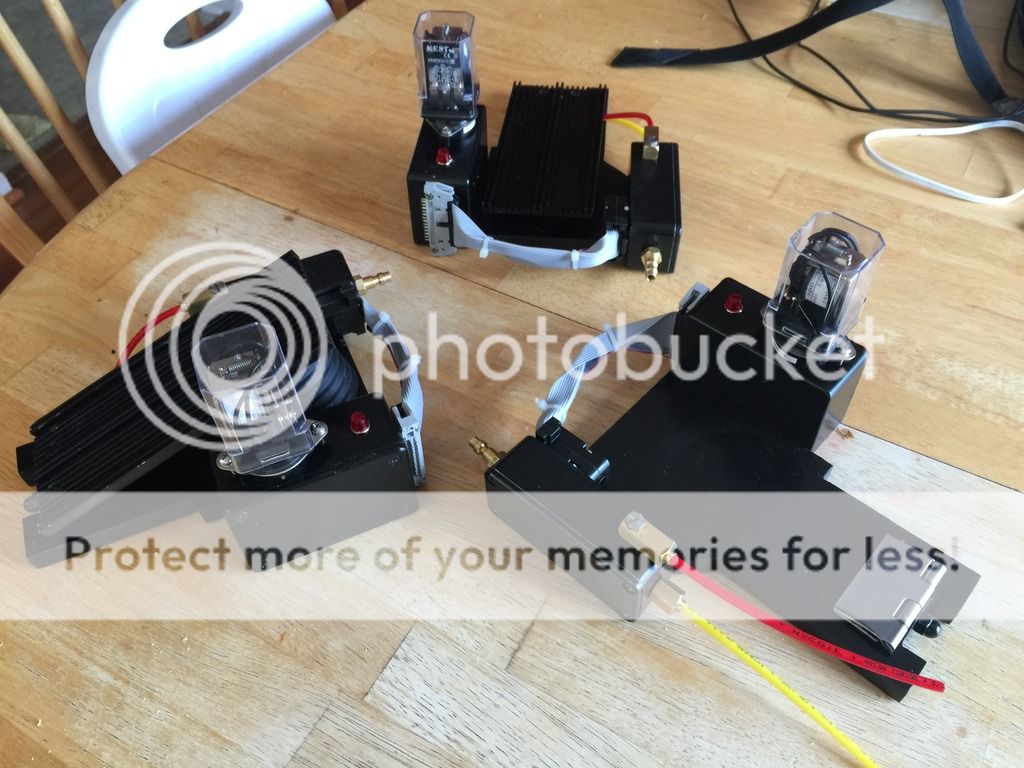

While I've been shopping options to cut the bodies, I've been amassing the greeblies. So far I have about 95% of the greeblies bought

-The money shot. I torgot to grab my bellows material for this shot.

-AJ's amazing Legris reps. I am in absolute awe of them.

-all the fosters!

-Researching front knobs have made me go cross eyed. I've decided to take these and paint them to match the screen used. I have some silver knobs lined up and need to source the fader knobs.

-Just some boxes.

-Proper 11pin sockets. The ITT relay was nigh impossible to source. The only vendor that had stock quoted me at $85/piece. Yikes! I have close enoughs on the way.

-EHC mil-spec knobs. The skirted dials are some random cheapoes I found just to cut 'em up.

-26 pin IDC and header from 3M. The Ribbon cable is in the big pic. It's standard 26 pin grey with a red trace.

-Vector plates from the GB fans shop. I'm still debating if the 6.5" plate needs to have the outer fins cut off, or if that was a GB2 thing.

-The pedal bases. They're being made on 1/2" craft ply. I rough cut them with my circ and miter saws. I'll be heading to Alex's tomorrow to sand them and finish the cuts.

The greeblies I have left to procur aren't too hard to get. The only one that's got me back on the rocks as far as availability is tge Cal-R. I had a vendor, but a min order of $50 is needed to pyrchse through them and they frankly have nothing else I'm interested in.

Still on the way are the 15 pin d sub connecters and the d sub hood. I purchased grey but will paint them black. Also, linrose lamps are on the way and eventually I need to sit down and program an arduino to handle all the fun electronics stuff.

While I've been shopping options to cut the bodies, I've been amassing the greeblies. So far I have about 95% of the greeblies bought

-The money shot. I torgot to grab my bellows material for this shot.

-AJ's amazing Legris reps. I am in absolute awe of them.

-all the fosters!

-Researching front knobs have made me go cross eyed. I've decided to take these and paint them to match the screen used. I have some silver knobs lined up and need to source the fader knobs.

-Just some boxes.

-Proper 11pin sockets. The ITT relay was nigh impossible to source. The only vendor that had stock quoted me at $85/piece. Yikes! I have close enoughs on the way.

-EHC mil-spec knobs. The skirted dials are some random cheapoes I found just to cut 'em up.

-26 pin IDC and header from 3M. The Ribbon cable is in the big pic. It's standard 26 pin grey with a red trace.

-Vector plates from the GB fans shop. I'm still debating if the 6.5" plate needs to have the outer fins cut off, or if that was a GB2 thing.

-The pedal bases. They're being made on 1/2" craft ply. I rough cut them with my circ and miter saws. I'll be heading to Alex's tomorrow to sand them and finish the cuts.

The greeblies I have left to procur aren't too hard to get. The only one that's got me back on the rocks as far as availability is tge Cal-R. I had a vendor, but a min order of $50 is needed to pyrchse through them and they frankly have nothing else I'm interested in.

Still on the way are the 15 pin d sub connecters and the d sub hood. I purchased grey but will paint them black. Also, linrose lamps are on the way and eventually I need to sit down and program an arduino to handle all the fun electronics stuff.

Kitten, what I'm saying is; sometimes, shit happens, someone's gotta deal with it, and who ya gonna call??

Hijacker's Pneumatic Emporium

Hijacker's Pneumatic Emporium

GB1 and GB 2 Uniform Build Thread:

GB1 and GB 2 Uniform Build Thread:

- By edspengler

- By edspengler - By Indy Magnoli

- By Indy Magnoli